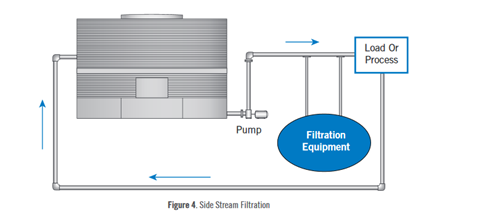

A major food manufacturer was running two Baltimore VX cooling towers at a site in West London. Upon advice from BAC these towers were fitted with side stream filtration to clean the sump water using their strainer basket method. The maintenance of these strainers requires that bypass piping is installed to allow the metal screen to be removed for cleaning.

Figure 1- Picture courtesy of Baltimore Aircoil

Figure 1- Picture courtesy of Baltimore Aircoil

Pollen and insects

The problems started to occur at the beginning of the pollen season. The factory is located in a built up area just off the A40. However, suburbs bring with them gardens, parks and open spaces and an increase of seed, dust, insects and pollen.

This debris was drawn into the

cooling tower and its defensive filtration system which struggled to cope with the sheer volume of particulate. Strainer maintenance and disinfection tasks increased in order to keep the water clean and the cooling tower efficient.

The Benefits of Clean Water

Reduced energy consumptionAs little as a 1/16” layer of dirt, scale, or biological deposits on heat transfer surfaces results in a loss of cooling tower efficiency, increasing energy costs.

Improved chemical performanceDirty water requires more chemicals to treat than clean water because a build-up of solid

contaminants provides a buffer that reduces the effects of treatment chemicals. Additional chemicals are then necessary.

Lower maintenance costFrequently draining a tower and cleaning sediment increases labour requirements, and results in added costs to replace lost water in the system and provide additional chemicals.

Improved productivity and less downtimeFouling a cooling system slows production because machines cannot run efficiently. A fouled heat exchanger could take a system down for an extended period of time until repairs are complete, resulting in less production per day and lost profits.

Control of biological growth that can lead to health problemsLegionella, bacteria that thrives in improperly maintained cooling tower environments, is particularly important to control because it poses significant health risks. Reducing outbreaks of the disease Legionellosis is discussed in ASHRAE Guideline 12-2000, entitled “Minimizing the Risk of Legionellosis Associated with Building Water Systems.

Solution

The two towers were due for replacement and the client issued the contract to Paul Cable, Managing Director at EJM Engineered Systems Ltd. Paul was also tasked with solving the

airborne particle problem.

Following a conversation with Richard Betts of

RABScreen it was agreed that new

air intake filters should be manufactured to enable the old towers to be kept clean and yet be interchangeable and easy to fit on the new towers.

RABScreen BHA filters with marine grade vinyl borders and stainless-steel grommets were selected together with the unique RABScreen MagnaMount™.

The MagnaMount™ is a magnetic, drop tab fitting that allows the filters to be easily fitted to the old towers without any drilling. When they are needed for the new towers the magnets can be released without removal from the filters and then fitted to protect the BAX VX units.

And what’s more it is safer too! No drilling with the risk of metal shards causing injury.